Diesel Generators for Capacitive Loads Understanding the Power of Efficiency

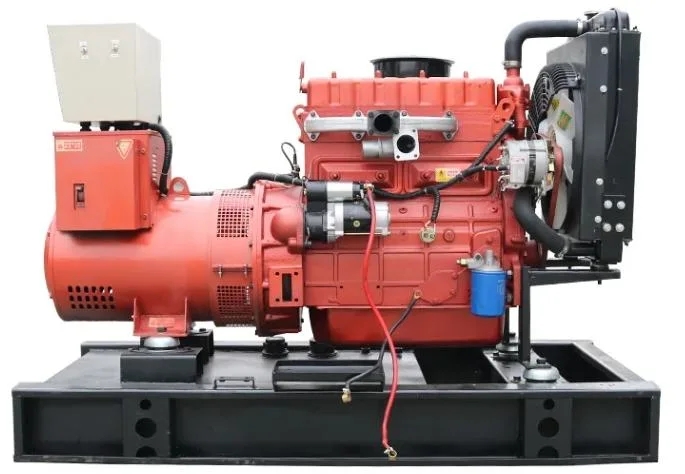

Introduction: Diesel generators have long been a reliable source of power generation for various applications, including industrial, commercial, and residential settings. One of the key challenges faced when using diesel generators is ensuring their efficiency and reliability, especially when powering capacitive loads. Capacitive loads, such as electric motors and capacitors, can present unique challenges to diesel generators due to their reactive power requirements. In this article, we will explore the principles behind diesel generators, the impact of capacitive loads on generator performance, and strategies for optimizing efficiency when powering capacitive loads. Understanding Diesel Generators: Diesel generators are a type of internal combustion engine that converts diesel fuel into mechanical energy, which is then converted into electrical energy through an alternator. The key components of a diesel generator include the engine, alternator, fuel system, cooling system, and control panel. The engine is responsible for converting the chemical energy in diesel fuel into mechanical energy through combustion, while the alternator converts this mechanical energy into electrical energy. The fuel system ensures a steady supply of diesel fuel to the engine, while the cooling system regulates the temperature of the engine to prevent overheating. The control panel monitors and controls the operation of the generator, ensuring optimal performance and safety. Diesel generators are known for their reliability, durability, and efficiency, making them a popular choice for applications where a steady and dependable power supply is required. However, diesel generators are not immune to challenges, especially when powering capacitive loads. Impact of Capacitive Loads on Generator Performance: Capacitive loads, such as electric motors and capacitors, exhibit a power factor that is less than unity, meaning they require both real power (kW) and reactive power (kVAR) to operate. When a diesel generator is used to power capacitive loads, the reactive power requirements can affect the generator's performance and efficiency. The presence of capacitive loads can lead to a lower power factor, increased voltage fluctuations, and reduced generator efficiency. One of the primary challenges of powering capacitive loads with a diesel generator is the mismatch between the real and reactive power requirements. Diesel generators are typically designed to provide real power, and when tasked with supplying reactive power to capacitive loads, the generator may operate outside of its optimal efficiency range. This can result in increased fuel consumption, higher maintenance costs, and reduced overall performance. Strategies for Optimizing Efficiency with Capacitive Loads: To overcome the challenges associated with powering capacitive loads with diesel generators, several strategies can be implemented to optimize efficiency and performance: 1. Power Factor Correction: Power factor correction (PFC) is a technique used to improve the power factor of a system by adding capacitors or reactors to offset the reactive power requirements of capacitive loads. By improving the power factor, the diesel generator can operate more efficiently and effectively when powering capacitive loads. 2. Sizing and https://www.lkpowerplant.com/what-is-75kw-diesel-generator/ : Proper sizing and selection of the diesel generator are essential when powering capacitive loads. The generator should be matched to the specific requirements of the capacitive loads, taking into account the real power, reactive power, and power factor considerations. Oversized or undersized generators can lead to inefficiencies and increased operating costs. 3. Load Management: Effective load management is crucial for optimizing the efficiency of a diesel generator when powering capacitive loads. By balancing the real and reactive power requirements of the loads, the generator can operate more efficiently and reliably. Implementing load shedding techniques and prioritizing critical loads can help minimize the impact of capacitive loads on generator performance. 4. Voltage Regulation: Voltage regulation is critical when powering capacitive loads with a diesel generator. Capacitive loads can cause voltage fluctuations and instability, which can lead to equipment damage and power quality issues. Implementing voltage regulation techniques, such as automatic voltage regulators (AVRs), can help maintain a stable voltage output and protect sensitive equipment from damage. 5. Maintenance and Monitoring: Regular maintenance and monitoring of the diesel generator are essential for ensuring optimal performance when powering capacitive loads. Routine inspections, servicing, and testing can help identify and address any issues that may impact efficiency and reliability. Monitoring the generator's performance, fuel consumption, and power quality parameters can provide valuable insights into its operation and help optimize efficiency over time. Conclusion: Diesel generators are a versatile and reliable power generation solution for a wide range of applications, including powering capacitive loads. Understanding the impact of capacitive loads on generator performance and implementing strategies to optimize efficiency are essential for maximizing the reliability and effectiveness of diesel generators in such applications. By addressing power factor considerations, proper sizing and selection, load management techniques, voltage regulation, and maintenance practices, diesel generators can efficiently and effectively power capacitive loads while ensuring reliable and uninterrupted power supply. Optimizing the efficiency of diesel generators for capacitive loads is key to achieving long-term operational success and cost savings in various industries and settings.